SPI rectangular silencers

SPI rectangular silencers

Characteristics

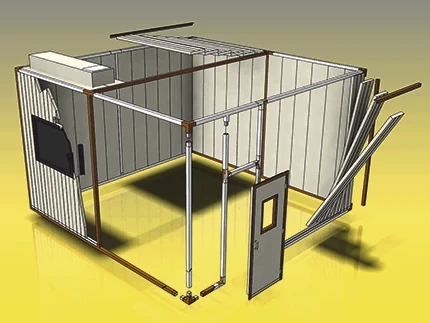

SPI rectangular acoustic silencers from SINTEC are a crucial element to diminish the noise through ventilation ducts or openings, independently from the sound source.

Its operation is based on the parallel layout of the cells, which are made of a sound absorbing material. These cells have a certain separation among them in order to create independent air passages. Air circulation is channelled through these passages, thus creating a dissipative action against the sound waves going through.

The dampening performance of a SPI acoustic silencer depends on the separation between the cells and its length, which is equal to the distance that the air must travel when going through.

Composition

Galvanised sheets of soundproofed cells, made from central and longitudinal ribbed cold profiled trays and 55 km3 rock wool, protected with black veil on both sides.

The external envelope is made of galvanised plate with a thickness of 1.2mm.

The reinforcements on the entire perimeter are carried out using hot-rolled steel with a thickness of 5mm on both ends of the silencer, which are also used as fixing elements during installation.

Flow entry aerodynamic profile.

Highlights:

Reinforced construction. SPI acoustic silencers have been specially designed to withstand tough use in all types of installations, both industrial and civil. The structural perimeter profile and the great thickness of the enclosure withstand the vibrations that may come from the installation.

Mineral absorbent block. In contrast to other manufacturing types, the mineral absorbent is made as a single solid block. This prevents disbondment and a premature wear of the fibrous component.

Lateral absorbent elements. Besides central cells, SPI silencers have lateral absorbent elements to reduce the insulation loss due to a poor absorption on the sides.

Data sheet

Manufacturing

At our facilities we have the latest technology and machinery necessary to design and manufacture all our products with absolute precision.

To obtain the desired results, it is essential to adapt the product to the specific needs of the client.

Facility

We design, manufacture and install bespoke solutions, according to the project requirements and the needs of the client.

Our fitters, alongside the installation control technicians, will complete any acoustic solution you need.

Applications

Air renewal for acoustic enclosures.

Cogeneration systems.

Machinery rooms.

Industrial refrigeration.

Ventilation systems.

Power generators.

Air renewal in technical rooms...